Binary Dice build improvement

It all started with a question from a visiting buddy. "How did you make the dice?" And it ended with a new and improved method for making boolean/binary d2 dice for board games, and 2 sets of 5dbool.

We were playing a round of The Royal Game of Ur, and chatting about making stuff. When I explained the process as:

- cut 4 cubes

- shake a can of stain

- open the can

- dab a pencil eraser into the stain on the inside of the lid

- stamp a pencil eraser shaped "circle" onto 3 sides of a cube

it did not elicit a joyous satisfaction of 'completion'. So off to the wood shop I went to revisit my cube making process and see if I could find an enjoyable way to efficiently craft inproved dice for the Game of Ur.

The game needs binary 4d2, or 4d0/1? 4bool maybe? I still don't know what to call it, but a set of dice was made, and the crafting process once again did not quench the thirst.

Not a Joyous Satisfaction

There was something about staining pips on a wooden surface that just didn't sit well with me. It was quick and got the job done,

but there was certainly room for improvement. There gears were turning, but the next step was still eluding me.

There was something about staining pips on a wooden surface that just didn't sit well with me. It was quick and got the job done,

but there was certainly room for improvement. There gears were turning, but the next step was still eluding me.

Smudged Sloppy Pips

After applying boiled linseed oil to cubes, the uneven levels of stain smeared over the faces of the cube, and the contrast was

lower than I would have liked.

After applying boiled linseed oil to cubes, the uneven levels of stain smeared over the faces of the cube, and the contrast was

lower than I would have liked.

That's when the inspiration hit: the contrast can be improved by using a slice of Redwood as an inlay for the pips. Although I've never made an inlay in my shop, a round inlay should be easy enough with the proper cutting tools.

The plan at this point, is to make 2 sets of 5. 4 dice for the game, and sacrificial dice for testing various sanding methods and finishing oils. Doug Fir with Redwood inlay, and Redwood with Doug Fir inlay.

Tools Aquired

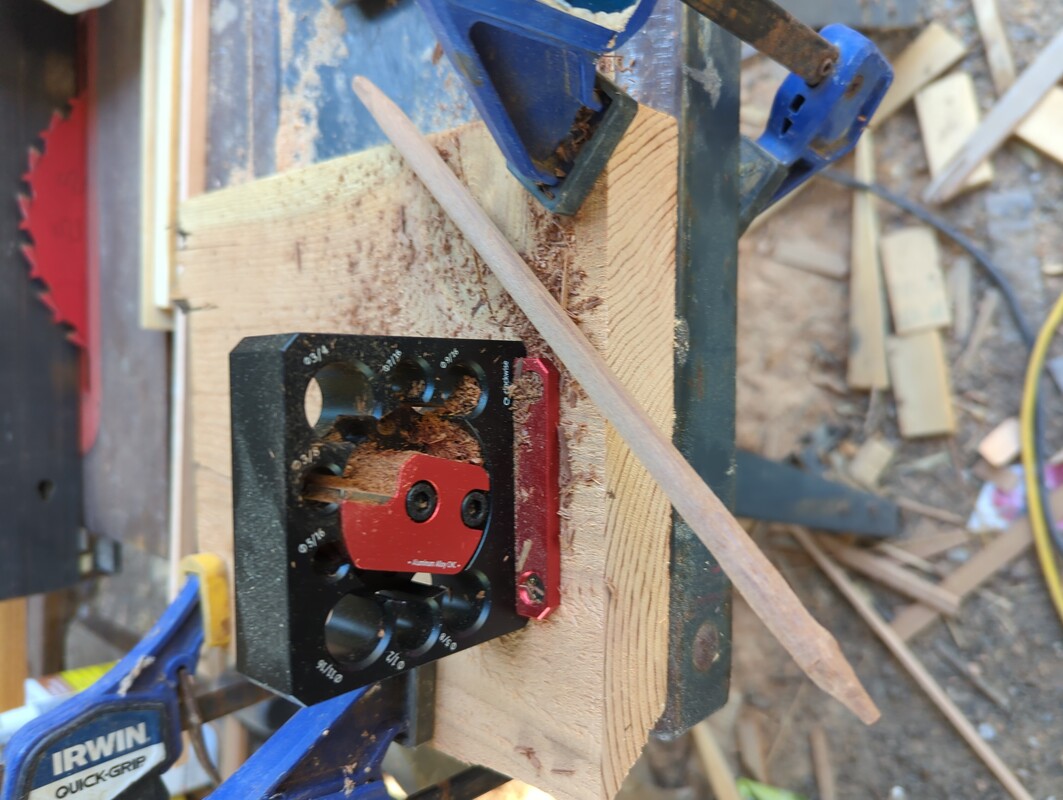

Earlier this Summer I purchased this cutting tool, and it was pleasing to finally put it to use. After this

Redwood dowel was cut, I cut another Redwood dowel as well as 2 Doug Fir dowels (also at 3/8"). The Doug Fir dowels were rough and had some flat spots as

well as a good bit of chipping.

Earlier this Summer I purchased this cutting tool, and it was pleasing to finally put it to use. After this

Redwood dowel was cut, I cut another Redwood dowel as well as 2 Doug Fir dowels (also at 3/8"). The Doug Fir dowels were rough and had some flat spots as

well as a good bit of chipping.

Making Slices

Using a bandsaw and some pen marks on a simple jig, the dowel was sliced to make inserts. Prior to cutting the dowel, I gave the dowel a quick

sanding with power tools that I now regret. The dowel was smooth, but the final fitment sometimes had small gaps.

Using a bandsaw and some pen marks on a simple jig, the dowel was sliced to make inserts. Prior to cutting the dowel, I gave the dowel a quick

sanding with power tools that I now regret. The dowel was smooth, but the final fitment sometimes had small gaps.

Cutting Insets

A 3/8" forstner bit cut the insets. Some of the insets were drilled a bit too deep. A bit more attention here would avoid headaches later.

A 3/8" forstner bit cut the insets. Some of the insets were drilled a bit too deep. A bit more attention here would avoid headaches later.

Pips!

A small dot of wood glue is placed in the inset, and then a pip slice is pressed into the inset. A small piece of scrap wood, used as a mallet, makes sure the slices are in there.

A small dot of wood glue is placed in the inset, and then a pip slice is pressed into the inset. A small piece of scrap wood, used as a mallet, makes sure the slices are in there.

Pipping the Redwood Dice

Once the pipping glue had dried. The 2 tester dice were held together in a clamp and had one face sanded smooth. It was iresome. The next test was hand sanding, which I found

to be preferable once any tall standing pips were shaved down with the bandsaw. A sanding belt in my bandsaw might be an even better solution. Time will tell on that one.

Once the pipping glue had dried. The 2 tester dice were held together in a clamp and had one face sanded smooth. It was iresome. The next test was hand sanding, which I found

to be preferable once any tall standing pips were shaved down with the bandsaw. A sanding belt in my bandsaw might be an even better solution. Time will tell on that one.

Finished!

For both sets, the first test of finishing oil looked good enough for me to not bother testing any other oils. Danish Oil for the win!

For both sets, the first test of finishing oil looked good enough for me to not bother testing any other oils. Danish Oil for the win!

As the oil was being applied, it became obvious where any wood glue was present on the suface of the dice. A few swipes off sandpaper removed any prominent bits of glue.

cheers,

jezra